|

Alloy Wheels Carbon Wheels Bearing Adjustment Alloy Rims Hub Assembly Hub Maintenance Spokes Alloy Wheel Building Home Your Shopping Cart |

Hub Maintenance

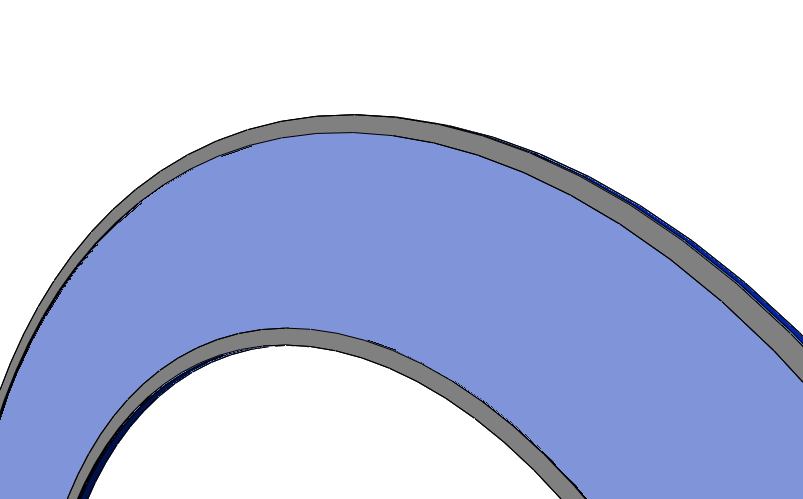

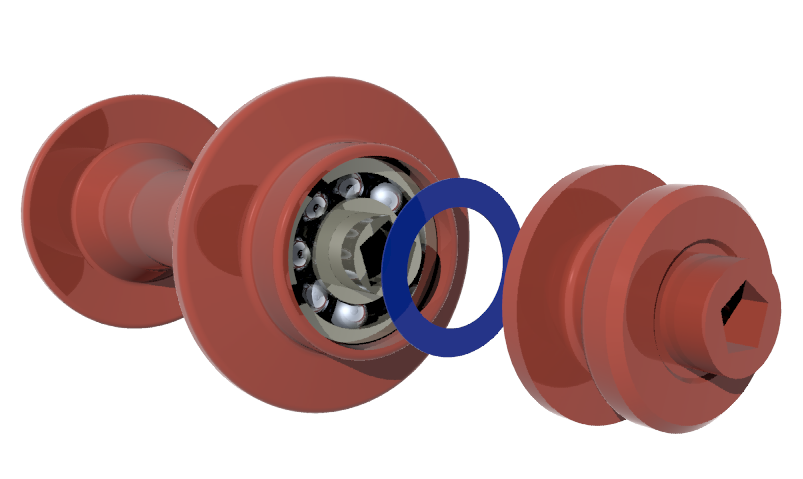

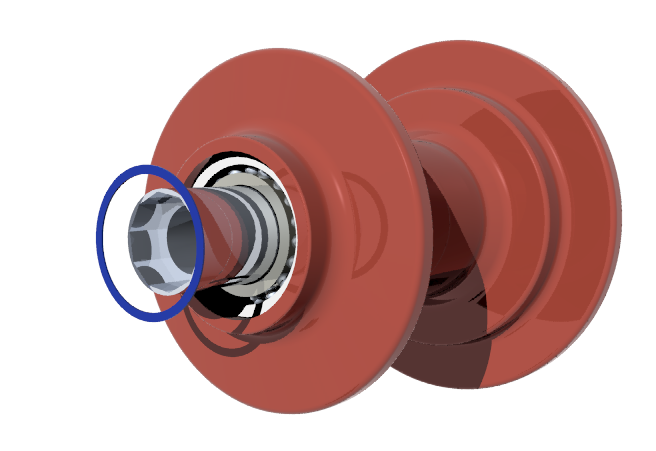

The only hub maintenance required is lubricating the bearings. If they are not contaminated, that could be as long as 10,000 miles. If they are (power hosing in a cross race) they should be immediately relubricated. The process is to remove the seals that are on the sealed cartridge bearing. Above is a rendering of the inside of the seal showing two seals. One on the upper and and one on the lower edge. The upper seal is a press fit into the outer bearing race. The inner seal is the contact seal that slides over the inner race. There are different kinds of seals but they all provide a minimal amount of contact.

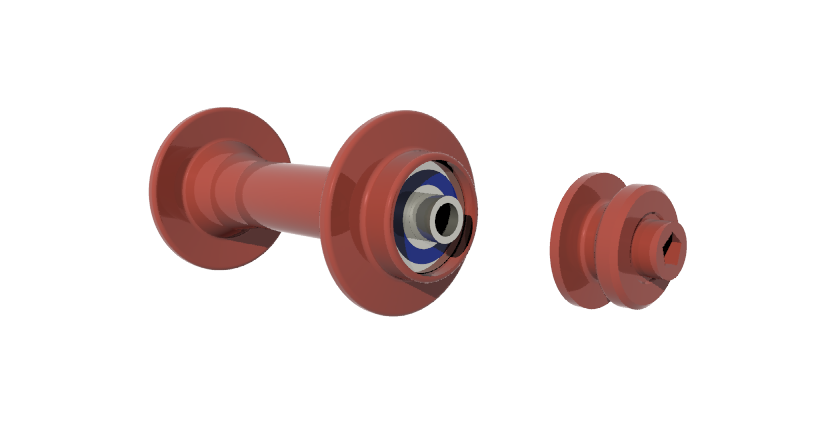

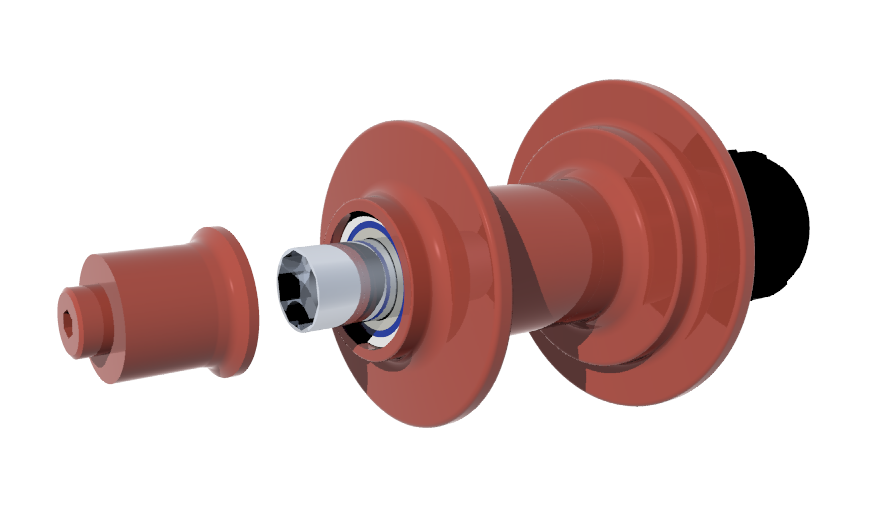

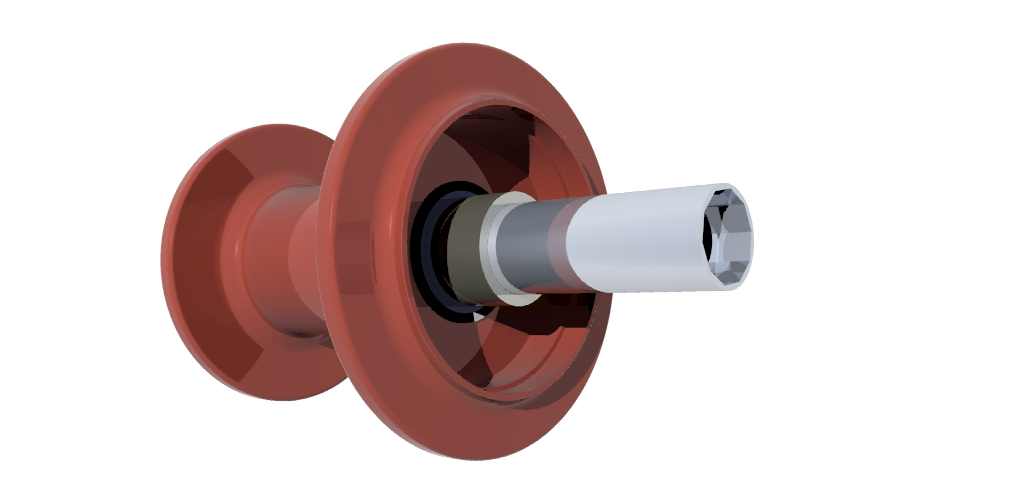

Front Hub: Remove end cap with 5 mm allen key. Remove seal, lube. The end of the axle is broached so use an allen key in the end of the axle to unscrew the other side and do the same thing. Use a small amount of grease on the threads of the end caps and just tighten to a snug fit. Don’t overdo it - the quick release holds the end caps on anyway.

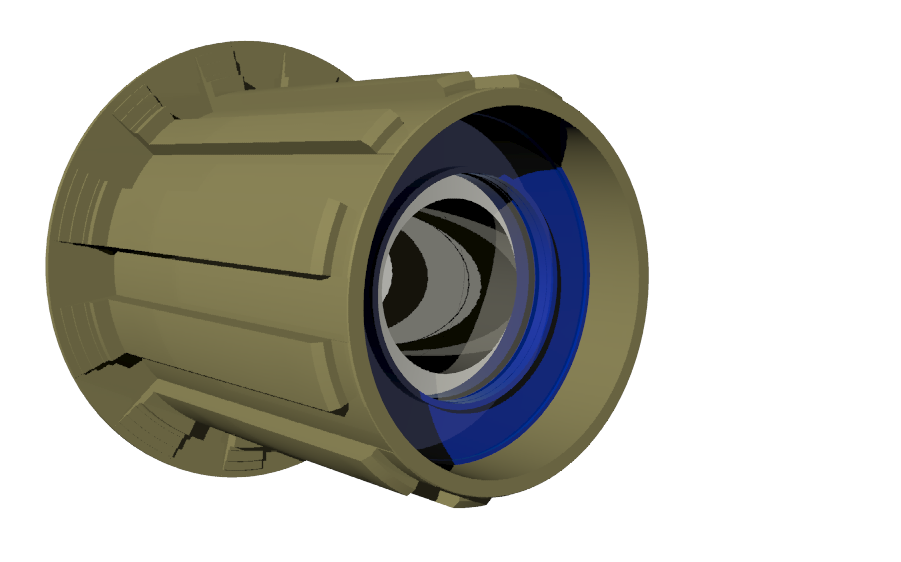

Rear Hub: Remove the end caps with a 5 mm allen key. The rear axle is broached for a 10 mm allen key. Do the same thing as on the front hub. The cassette body has two bearings. The internal bearing is not serviceable without removing it - which cannot be done without special bearing presses. Since it’s internal there is little change of it getting contanimated. There is a seal on the outside that needs to be removed before you can access the outboard bearing. Remove it the same way you remove the bearing seals.

|