|

Alloy Wheels Carbon Wheels Spokes Alloy Wheel Building Bearing Adjustment Hub Assembly Hub Maintenance Home Your Shopping Cart |

Alloy Rims

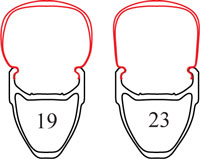

Our 23 mm wide rims are over 20 percent wider than standard 19 mm wide rims. This results in a much better handling, performance, and aerodynamics. The drawing above shows a conventional 19 mm wide rim on the left and a 23 mm wide rim on the right. Note how the base of the tire offers a straighter sidewall and more support - much like a tire on race car.

When Mavic introduced wheel systems in the 80’s, they were the first to offer a wide varitey of lower spoke count wheels. Because they designed the hubs as well as the spokes for their “system” they were the first to use 20, 24 and even lower spoke counts on their wheels. The fewer spokes the more aerodynamic the wheels are because spoke act much like egg beaters. This mean their systems were a lot faster than normal 32 or 36 spoke wheels but it came at a price of more wheel failures. In particular, rear wheels would often fail at the spoke holes - which is no surprise since having 20 or 24 spokes instead of 32 or 36 means there are far fewer spokes supporting the rider.

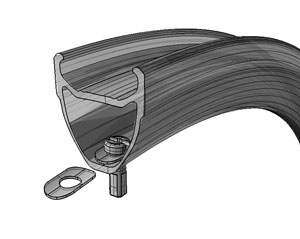

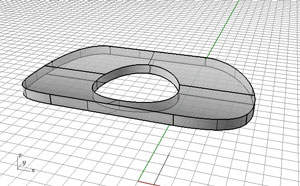

We have found over 95% of alloy rim cracks occur on the drive side of the rear wheel so we use special washers custom designed, and made in the US, to mate with our rims on alloy rear wheels. This not only provides a wider base to support the spoke head but allows us to build to much higher tension resulting in longer wheel life. In addition, because the spoke nipple is seated on the washer instead of the rim it doesn’t deform the spoke hole as the wheel is being built. The rim rendering above shows how the washer transfers the load of the spoke head over a larger area. The outside dimensions of the washer are 12X6.5 mm, while the spoke head is a 6 mm in diameter. In addition, the washers are made of .5 mm thich stainless steel - adding additional thickness to the spoke bed (which is 2 mm thick). |